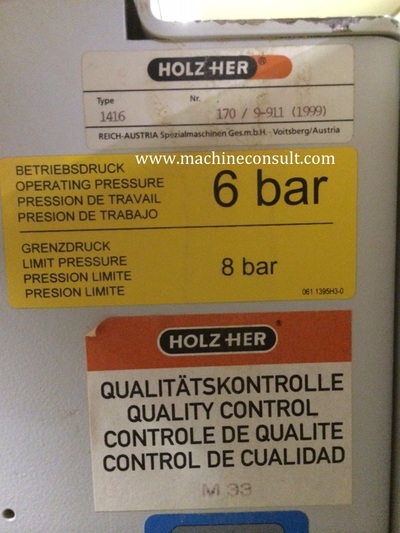

Holz Her Model 1416 Year 1999

Machine Type: 8mm Capable Lineal Edgebander

Condition: Good, was pulled from service in working condition, replaced by new machine. Full Description Below

Elect./Voltage: 220V, 60 Cy, 3 Ph.

Appr. Repl. Cost: $ 55,000.00

Asking Price: $ 5,000.00

fob: KS

Click Here for more info.

Condition: Good, was pulled from service in working condition, replaced by new machine. Full Description Below

Elect./Voltage: 220V, 60 Cy, 3 Ph.

Appr. Repl. Cost: $ 55,000.00

Asking Price: $ 5,000.00

fob: KS

Click Here for more info.

Description:

Used HOLZ-HER Sprint 1416 Edgebander (1999)

- cartridge glue

- end trim

- rough trim

- fine trim

- PVC scraper

- corner round unit

- glue scraper

- jump buffing

SPECIFICATIONS for Holz-Her Model 1416 Sprint Series Edgebander

• Efficient design using latest engineering and manufacturing techniques

• Heavy duty design using the best available components

• Quickest changeover time in the industry (takes just seconds)

• Quickest heat-up time in the industry (3 - 5 minutes)

• Patented glue systems require less than half the energy consumption of standard

glue pots

• State-of-the-art electronic control systems

• Can be configured to meet virtually any edgebanding application

• Same Day Parts Shipment Guarantee

BASIC MACHINE:

PROGRAMMABLE LOGIC CONTROL (PLC)

• Ability to program all edgebander functions including: edge feed, glue application, end trimming, flush trimming, radius trimming, scraping, corner rounding, and buffing.

• Programs can be easily created and recalled at will.

• Screen with graphic interface makes programming easy.

• A picture of each unit may be brought up on the screen to show the operator the status of the unit and the parameters which can be programmed.

• Virtually eliminates set-up time by merely selecting and loading a program, which automatically activates all required edgebander functions simultaneously.

• Each program clearly indicates on screen the units included and their exact settings.

• Programs can be modified easily to create new programs.

• Edgebander can be operated manually when required, without necessity to write a program.

• Eliminates use of limit switches and their normal adjustments related to work station activation along the feed track.

• Error messages are presented in plain text, to avoid the need for endless error code lists.

• Eliminates many mistakes caused by lack of operator skill.

• Latest technology offering many exclusive features and demonstrating HOLZ-HER’s continued leadership in the market.

MODEL 1901 EDGESTRIP MAGAZINE

• 1 (one) universal magazine for solid edges, strips, and coiled material.

• Utilizes motion detector to ensure accurate, trouble-free positioning of edge material.

• Exclusive “TRACTOR-BELT FEED SYSTEM” to ensure accurate, trouble-free feeding of edge material, as well as optimum operator safety.

• Angled strip gate to prevent double feeding of strips.

• Magazine table on rollers for smooth feeding of coiled material.

• Edge guide equipped with automatic guillotine lock-out for safety.

• “3 DEGREE APPROACH ANGLE” allows easy feeding of large wood edges.

• Automatic guillotine for coiled material up to 4.0 mm.

MODEL 1906 GLUING STATION - “CARTRIDGE SYSTEM”

• Equipped with HOLZ-HER'S exclusive patented "CARTRIDGE" glue system. This is a CLOSED APPLICATION SYSTEM in which the glue is enclosed in an air- tight chamber and cannot oxidize, discolor, burn, or become contaminated with wood dust. This allows for optimum glue adhesion.

• Glue applied to panel by patented GLUE NOZZLE from 6-45mm workpiece thickness.

• Precise control of all functions including begin and end of glue line, height of glue line, bottom of glue line, volume of glue and face melt temperature.

• Less maintenance - no glue pot to clean, fewer parts.

• Efficient glue consumption - virtually no waste.

• Efficient power consumption - uses less than half that of conventional glue pots.

• Fastest & easiest glue color change, 5-10 min.

• Fastest heat-up time in the industry, less than 3 min.

• No fumes or other environmental hazards.

• Machine can be used for trimming without heating up the glue section.

MODEL 1913 - P PNEUMATIC PRESSURE UNIT

• Large electronically-driven roller synchronized with feed speed.

• Two additional rollers are cantered enabling high gluing pressure and precise banding.

• Quick adjustment of pressure section to edge thickness by means of speed wheel and scale.

MODEL 1918 END TRIM UNIT

• Heavy duty finish with linear guide bars for precision and trimming.

• Two high frequency motors for cutting the leading and trailing edges with draw cuts. (up to 8 mm)

• Mounted with uni-point axis enabling quick change for chamfer trimming up to 10?.

• Mechanically indexes ends for a perfect finish.

• Motors: 2 x .22 KW Speed 9,000 RPM.

• Maximum edge thickness up to 13mm.

• “PCS” Pneumatic Changeover System included as standard

MODEL 1823 FLUSH TRIM UNIT

• Two high frequency motors for top and bottom rough trimming

• Vertical Tracing Wheels

• Maximum Edgestrip Thickness: 13mm

• Motor: 2 x 0.6 KW (.82 HP), 300 HZ, Speed 18,000 RPM

MODEL 1942-M COMBINATION FLUSH, CHAMFER & RADIUS TRIM UNIT

• Two high frequency motors for edge trimming 0 to 15 degrees.

• Vertical and horizontal tracing with uni-point design for no second adjustment when changing the degree of bevel.

• Maximum edgestrip thickness: 8 mm.(Standard) 13 mm with optional straight tooling.

• Air jets for debris removal.

• Radius capability up to 3 mm radius.

• Motor: 2 x 0.6 KW (.82 HP), 300 HZ, Speed 18000 RPM.

• “PCS” Pneumatic Changeover System from flush to radius from control panel included as standard

• Digital counters included.

MODEL 1929 SCRAPER UNIT

• Uses reversible insert carbide scraping knives on the top and bottom edges.

• Normally equipped with radius tooling to finish and remove knife marks created by the top,bottom, and radius units on thick PVC edgings. (2,3 mm).

• Equipped with air-jet blowers.

• Vertical and horizontal copy wheels.

• “PCS” Pneumatic Changeover System moves Scraper Unit in and out from control panel.

• Equipped with digital readouts for all adjustment spindles.

MODEL 1983 CONTOUR TRIMMING UNIT, H.F. WITH AIR JET

• For rounding of corners: radius, chamfer, or flush trim.

• Possible radius: 2 mm and 3 mm.

• One motor, 1 x 0.6 KW, 300 HZ.

• Feed speed of 12 meters per minute. Max.

• Includes 7 Siko digitals for quick set-up.

• Equipped with reversible blade cutterhead with radius knives.

MODEL 1944K PLUNGE BUFFING UNIT

• Includes two motors with the possibility of adjustment in any direction.

• Incorporates “plunge control” to avoid rounding-over the leading and trailing edges, and ensure tight corners (thick PVC).

• Horizontal Swivel = 0 to 20 º.

• Equipped with cloth buffing wheels for smoothing the sharp edges of thin PVC band after trimming.

• Can be equipped with fine sanding wheels for finishing wood and laminate edges.

• Motor Speed = 1440 RPM.

TECHNICAL DATA:

Machine Dimensions:

Length: 3250 mm / 128 in.

Width: 1470 mm / 58 in.

Height: 1200 mm / 47 in.

Working Dimensions:

Edge Strip Thickness: 0.3 - 13mm

Edge Strip Width: 50mm

Edge Strip Length: 200mm minimum - Unlimited

Workpiece Width: Min. 60mm

Workpiece Length: Min. 180mm

Workpiece Thickness: 6 - 45mm

Feed Speed: 12 m/min

(12~16mpm with Optional Variable Track

Speed)

Air Requirement: 6 bar

Shipping Dimensions:

17ft L x 4ft 9in W x 6ft 3in H

Used HOLZ-HER Sprint 1416 Edgebander (1999)

- cartridge glue

- end trim

- rough trim

- fine trim

- PVC scraper

- corner round unit

- glue scraper

- jump buffing

SPECIFICATIONS for Holz-Her Model 1416 Sprint Series Edgebander

• Efficient design using latest engineering and manufacturing techniques

• Heavy duty design using the best available components

• Quickest changeover time in the industry (takes just seconds)

• Quickest heat-up time in the industry (3 - 5 minutes)

• Patented glue systems require less than half the energy consumption of standard

glue pots

• State-of-the-art electronic control systems

• Can be configured to meet virtually any edgebanding application

• Same Day Parts Shipment Guarantee

BASIC MACHINE:

PROGRAMMABLE LOGIC CONTROL (PLC)

• Ability to program all edgebander functions including: edge feed, glue application, end trimming, flush trimming, radius trimming, scraping, corner rounding, and buffing.

• Programs can be easily created and recalled at will.

• Screen with graphic interface makes programming easy.

• A picture of each unit may be brought up on the screen to show the operator the status of the unit and the parameters which can be programmed.

• Virtually eliminates set-up time by merely selecting and loading a program, which automatically activates all required edgebander functions simultaneously.

• Each program clearly indicates on screen the units included and their exact settings.

• Programs can be modified easily to create new programs.

• Edgebander can be operated manually when required, without necessity to write a program.

• Eliminates use of limit switches and their normal adjustments related to work station activation along the feed track.

• Error messages are presented in plain text, to avoid the need for endless error code lists.

• Eliminates many mistakes caused by lack of operator skill.

• Latest technology offering many exclusive features and demonstrating HOLZ-HER’s continued leadership in the market.

MODEL 1901 EDGESTRIP MAGAZINE

• 1 (one) universal magazine for solid edges, strips, and coiled material.

• Utilizes motion detector to ensure accurate, trouble-free positioning of edge material.

• Exclusive “TRACTOR-BELT FEED SYSTEM” to ensure accurate, trouble-free feeding of edge material, as well as optimum operator safety.

• Angled strip gate to prevent double feeding of strips.

• Magazine table on rollers for smooth feeding of coiled material.

• Edge guide equipped with automatic guillotine lock-out for safety.

• “3 DEGREE APPROACH ANGLE” allows easy feeding of large wood edges.

• Automatic guillotine for coiled material up to 4.0 mm.

MODEL 1906 GLUING STATION - “CARTRIDGE SYSTEM”

• Equipped with HOLZ-HER'S exclusive patented "CARTRIDGE" glue system. This is a CLOSED APPLICATION SYSTEM in which the glue is enclosed in an air- tight chamber and cannot oxidize, discolor, burn, or become contaminated with wood dust. This allows for optimum glue adhesion.

• Glue applied to panel by patented GLUE NOZZLE from 6-45mm workpiece thickness.

• Precise control of all functions including begin and end of glue line, height of glue line, bottom of glue line, volume of glue and face melt temperature.

• Less maintenance - no glue pot to clean, fewer parts.

• Efficient glue consumption - virtually no waste.

• Efficient power consumption - uses less than half that of conventional glue pots.

• Fastest & easiest glue color change, 5-10 min.

• Fastest heat-up time in the industry, less than 3 min.

• No fumes or other environmental hazards.

• Machine can be used for trimming without heating up the glue section.

MODEL 1913 - P PNEUMATIC PRESSURE UNIT

• Large electronically-driven roller synchronized with feed speed.

• Two additional rollers are cantered enabling high gluing pressure and precise banding.

• Quick adjustment of pressure section to edge thickness by means of speed wheel and scale.

MODEL 1918 END TRIM UNIT

• Heavy duty finish with linear guide bars for precision and trimming.

• Two high frequency motors for cutting the leading and trailing edges with draw cuts. (up to 8 mm)

• Mounted with uni-point axis enabling quick change for chamfer trimming up to 10?.

• Mechanically indexes ends for a perfect finish.

• Motors: 2 x .22 KW Speed 9,000 RPM.

• Maximum edge thickness up to 13mm.

• “PCS” Pneumatic Changeover System included as standard

MODEL 1823 FLUSH TRIM UNIT

• Two high frequency motors for top and bottom rough trimming

• Vertical Tracing Wheels

• Maximum Edgestrip Thickness: 13mm

• Motor: 2 x 0.6 KW (.82 HP), 300 HZ, Speed 18,000 RPM

MODEL 1942-M COMBINATION FLUSH, CHAMFER & RADIUS TRIM UNIT

• Two high frequency motors for edge trimming 0 to 15 degrees.

• Vertical and horizontal tracing with uni-point design for no second adjustment when changing the degree of bevel.

• Maximum edgestrip thickness: 8 mm.(Standard) 13 mm with optional straight tooling.

• Air jets for debris removal.

• Radius capability up to 3 mm radius.

• Motor: 2 x 0.6 KW (.82 HP), 300 HZ, Speed 18000 RPM.

• “PCS” Pneumatic Changeover System from flush to radius from control panel included as standard

• Digital counters included.

MODEL 1929 SCRAPER UNIT

• Uses reversible insert carbide scraping knives on the top and bottom edges.

• Normally equipped with radius tooling to finish and remove knife marks created by the top,bottom, and radius units on thick PVC edgings. (2,3 mm).

• Equipped with air-jet blowers.

• Vertical and horizontal copy wheels.

• “PCS” Pneumatic Changeover System moves Scraper Unit in and out from control panel.

• Equipped with digital readouts for all adjustment spindles.

MODEL 1983 CONTOUR TRIMMING UNIT, H.F. WITH AIR JET

• For rounding of corners: radius, chamfer, or flush trim.

• Possible radius: 2 mm and 3 mm.

• One motor, 1 x 0.6 KW, 300 HZ.

• Feed speed of 12 meters per minute. Max.

• Includes 7 Siko digitals for quick set-up.

• Equipped with reversible blade cutterhead with radius knives.

MODEL 1944K PLUNGE BUFFING UNIT

• Includes two motors with the possibility of adjustment in any direction.

• Incorporates “plunge control” to avoid rounding-over the leading and trailing edges, and ensure tight corners (thick PVC).

• Horizontal Swivel = 0 to 20 º.

• Equipped with cloth buffing wheels for smoothing the sharp edges of thin PVC band after trimming.

• Can be equipped with fine sanding wheels for finishing wood and laminate edges.

• Motor Speed = 1440 RPM.

TECHNICAL DATA:

Machine Dimensions:

Length: 3250 mm / 128 in.

Width: 1470 mm / 58 in.

Height: 1200 mm / 47 in.

Working Dimensions:

Edge Strip Thickness: 0.3 - 13mm

Edge Strip Width: 50mm

Edge Strip Length: 200mm minimum - Unlimited

Workpiece Width: Min. 60mm

Workpiece Length: Min. 180mm

Workpiece Thickness: 6 - 45mm

Feed Speed: 12 m/min

(12~16mpm with Optional Variable Track

Speed)

Air Requirement: 6 bar

Shipping Dimensions:

17ft L x 4ft 9in W x 6ft 3in H

Mid America Woodworking Machinery, Inc. (All Rights Reserved)